Tips on selecting the appropriate caster for your application

Casters are special housings that include wheels and they facilitate those wheels being attached to equipment. Many people interchange the terminology of wheels and casters as meaning the same thing and for the most part that works out to be accepted.

However, when we want to really analyze the subject of casters, it is important to break them down into all of the important components. Components such as the wheel, the tread of the wheel, the barring that make the wheel spin, the mounting plate, and even how the wheel locks and swivels are important to know and understand.

A caster is simply designed for mobility of equipment. The equipment needs to be mobile, whether it sits in a corner of a commercial kitchen and only needs to be moved for easy access for cleaning, or if it’s a large banquet cabinet that needs to be loaded onto trucks and moved to off-site locations. These two applications require different consideration when it comes to wheel tread, hubs, and bearings.

A caster is simply designed for mobility of equipment. The equipment needs to be mobile, whether it sits in a corner of a commercial kitchen and only needs to be moved for easy access for cleaning, or if it’s a large banquet cabinet that needs to be loaded onto trucks and moved to off-site locations. These two applications require different consideration when it comes to wheel tread, hubs, and bearings.

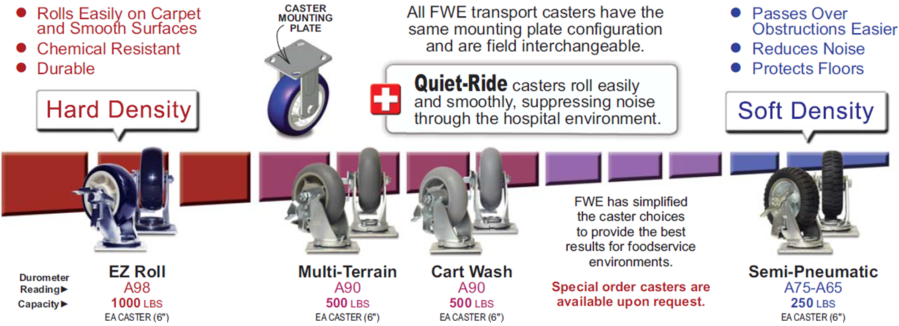

A caster that supports equipment without being moved very often can tend to get flat spots from sitting still, so a wide dense tread with bearings that require little to no maintenance is best. Adversely, equipment that will be pushed over thresholds, bumps and gravel, roll well with a soft tube-less semi-pneumatic tread, with Zerk grease lubricated raceways and bearings.

The environment the equipment is in can play a large part in your purchasing decision as well. The bulk food warming cabinet that hangs out in the corner of a commercial kitchen needs a caster that can roll on the smooth surfaces of the kitchen floor while being resistant to the cleaning agents that are used when cleaning those floors. Some applications, such as in healthcare patient meal delivery, need casters that can roll around hushed environments on equipment that must be as quiet and tranquil as possible. These delivery cabinets, in the highly sanitized healthcare facilities, are commonly spray washed inside and out. Without the properly sealed bearings, the casters will become corroded from the cleaning.

Size matters but bigger are not always better.

If the cabinet is one that will be sliding in and out from under a counter, being sure to pick the correct size caster will be paramount in your decision. It should also be known that typically the larger the wheel diameter is the easier it will roll.

Remember this terminology for the size of your caster;

Remember this terminology for the size of your caster;

- Wheel Diameter– This is the distance measured vertically from one side of the tread to the other.

- Overall Height – the total distance the caster raises the cart of the ground from the tread to the fastener plate.

- Tread Width – The distance measured laterally across the tread.

Generally, the larger the casters are, the higher the load capacity they can carry. This becomes spread out across all of the casters, so if you have typically four casters on your cabinet, you will divide your total weight across the four casters. Assuming you have a cabinet that weighs 100lbs and it has a load weight of 900lbs, your total weight would be 1000lbs. As stated before, this weight will be divided by each caster giving you a total of 250lbs per caster.

View the “Tips on Selecting Casters” by clicking here.

Credit: Chef Nate Sanford, CFSP at foodservice.me